This article provides an in-depth look at packaging machines, exploring their functions, types, and the advantages they offer in various industries. It discusses the importance of selecting the right packaging machine for businesses that require packaging for their products. The article also covers the different types of packaging machines available and highlights the benefits of using such equipment, including labor savings, efficiency, and enhanced product safety.

What is a Packaging Machine?

A packaging machine is a device used to package a variety of products. It not only protects the products from damage but also enhances their appeal with a clean and attractive appearance. These machines are widely used across multiple industries, including food, pharmaceuticals, cosmetics, hardware, and publishing. In modern manufacturing and sales, the role of packaging machines is indispensable, and for any business that sells packaged products, choosing a high-quality packaging machine is crucial.

Functions of Packaging Machines

The operation of a packaging machine includes steps such as material loading, weighing, bag forming, date printing, filling, sealing, cutting, and counting. Optional components like material loaders and date printers can be included based on specific needs. Controlled by a PLC touch screen, these machines allow for the customization of packaging speed, sealing temperature, and bag length, and can display the quantity of items packaged. Multiple motors independently control different circuits, ensuring stable and quiet operation. The machines can produce various bag styles, including back seal, three-side seal, four-side seal, and pyramid seal, with the sealing style determined by the sealing and cutting mechanisms.

Types of Packaging Machines

Packaging machines are classified based on their functions and the nature of the products they handle. Types include powder, liquid, granule, paste, lapel, pillow, and vacuum packaging machines. They can also be categorized by the level of automation (automatic or semi-automatic) and the industry they serve, such as food, cosmetics, textiles, etc. Additionally, there are custom-designed machines for specific packaging forms, like PPM bag packaging equipment.

Advantages of Packaging Equipment

Packaging machines offer numerous advantages, such as labor savings, improved efficiency, and enhanced food safety through hygienic packaging. The use of photoelectric sensors and servo film conveyor systems ensures precise bag positioning. The PLC touchscreen provides an intuitive interface for setting various parameters. Durable materials protect the packaged items, and effective sealing helps preserve the contents by preventing oxygen and moisture intrusion, thus extending product shelf life. The portable bags produced are convenient for consumers, and the neat packaging design can attract more customers, increasing sales potential.

Common Accessories for Packaging Equipment

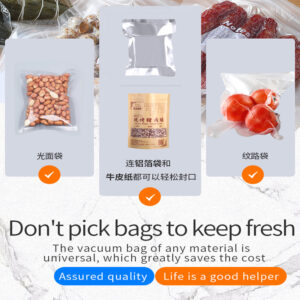

A variety of auxiliary equipment is used in conjunction with packaging machines, including date printers, conveyor belts, vacuum packaging equipment, sealing and punching devices, etc. Date printers can be ribbon or inkjet types, while conveyor belts facilitate automatic product transfer. Vacuum packaging equipment is suitable for preserving the freshness of food, and sealing and punching devices can create bags with holes for easy shelf display.

Packaging Machines from PPM Machine

PPM Machine offers a range of packaging machines for sale, including powder, granule, liquid, and paste equipment, as well as lapel and vacuum packaging machines. These machines are suitable for a wide array of applications and industries. We also provide customization services to meet specific packaging needs. For further interest or inquiries, please contact us as soon as possible.