The evolution of food packaging from simple wrapping to sophisticated design has not only enhanced product imagery but also brought significant economic benefits to food merchants, especially in terms of improving product safety and convenience.

I. Understanding Pre-packaged Food

Pre-packaged food offers convenience to consumers through precise portion control and uniform quality standards, while reducing the inventory management complexity and food safety risks for food merchants. Compared to bulk food, pre-packaged products are easier to trace, reducing potential contamination and waste, and increasing the added value of food.

II. Development Trends in Pre-packaged Food Packaging

Small Packaging

Small packaging has quickly become popular in the snack food sector for its portability and practicality. It meets consumer demands for healthy, portion-controlled diets and adapts to the lightweight packaging requirements of fast-paced living. Easy to store, small packaging reduces food waste, making it an ideal choice for office snacks and healthy foods.

Diversity

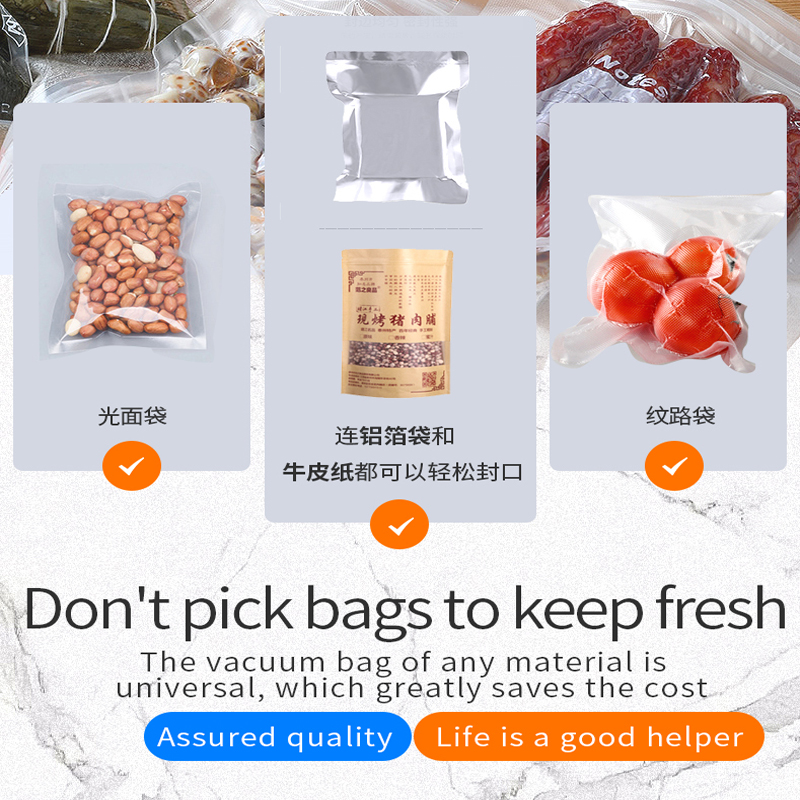

The diversity in food packaging is reflected in the application of various sizes and sealing technologies. This diversity meets the needs of different consumer groups, from small portable packs to family share packs, offering corresponding solutions. Diverse packaging designs not only increase market appeal but also provide food merchants with a wider range of marketing strategies.

Smart Packaging

Smart packaging represents the future of food packaging, integrating sensors, tracking technologies, and automated systems to improve packaging efficiency and accuracy. The application of fully automatic packaging machines reduces manual operations, enhances the level of automation on the production line, and ensures the consistency and reliability of packaging, giving food companies a strong competitive advantage.

Functional Packaging

Functional packaging is key to meeting specific food protection needs. Vacuum pack machines and nitrogen flushing technologies effectively extend the shelf life of food, while diverse sealing techniques provide customized protection solutions for different foods. The application of these technologies not only enhances the preservation capabilities of food but also offers consumers safer and more convenient food options, driving innovation and development in the packaging machinery industry.

III. The Importance of Food Packaging Machinery

Benefits

The automation and intelligence of food packaging machinery significantly increase production efficiency and reduce labor costs. By precisely controlling the packaging process, machinery ensures product consistency and quality, thereby enhancing the market competitiveness of enterprises. Moreover, efficient packaging machinery reduces material waste, saving costs and improving overall benefits for businesses.

Hygiene, Safety, and Environmental Protection

In the field of food packaging, the sanitary design of machinery and the safety of operations are crucial. Automated packaging machinery reduces the risk of food contamination by minimizing manual contact, and ensuring the hygiene and safety of food. At the same time, modern packaging machinery considers environmental protection in its design, using recyclable materials and reducing packaging material usage, aiding the food industry in achieving sustainable development.

Economy and Labor Reduction

The widespread use of food packaging machinery lightens the labor intensity for workers and reduces dependence on human resources. Automated technology makes the packaging process more stable and reliable, reducing losses due to human error. Additionally, reducing manual operations helps businesses maintain cost stability during economic fluctuations, enhancing their risk resistance.

Conclusion

The automation and intelligence level of the food packaging industry is continuously improving, with a rich variety of packaging equipment products effectively meeting the packaging needs of local products. The packaging machinery industry has broad development space and a promising future.