Pet Food Packaging Machine Overview

On the production line of pet food, packaging machines are responsible for sealing the products and ensuring the aesthetics and food safety of the packaging. These machines, through automation technology, achieve the entire process from filling to sealing, greatly improving production efficiency.

Functional and Components

Modern pet food packaging machines integrate several key components such as weighing systems, filling mechanisms, sealing units, and labeling systems. These components work together to ensure the accuracy and consistency of the packaging process.

Types of Pet Food Packaging Machines

There are mainly Vertical Form Fill Seal (VFFS) machines, automatic pouch packing machines, and multi-head weighing machines on the market. Enterprises choose the appropriate model based on their production needs and packaging characteristics.

Operation and Control Systems

The operation of pet food packaging machines relies on advanced PLC control systems and HMI interfaces, which not only improve the convenience of operation but also enhance the stability and reliability of the machines.

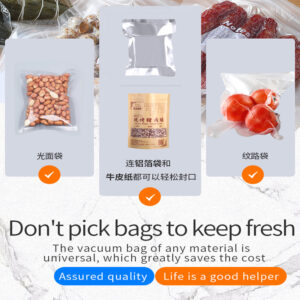

Hygiene and Safety Considerations

Hygiene and safety are the most important considerations in the pet food packaging process. Packaging materials must be food-grade, and machine design should facilitate cleaning and disinfection to maintain hygiene standards.

Maintenance and Troubleshooting

Regular maintenance and timely troubleshooting are key to ensuring the normal operation of packaging machines. This includes regular inspections, lubrication, and replacement of worn parts.

Industry Trends and Technological Development

With technological advancements, pet food packaging machines are becoming more intelligent and automated. New technologies such as the Internet of Things (IoT) and Artificial Intelligence (AI) are being integrated into packaging machines to achieve more efficient production and precise quality control.

Conclusion

Pet food packaging machines are indispensable in the pet food industry. They improve production efficiency and ensure product quality and safety. With the continuous advancement of technology, future packaging machines will be more intelligent and better meet market demands.