This article provides an overview of various methods and machinery for packaging different types of oils. It covers the nuances of packaging edible oils such as olive and peanut oils, as well as non-edible oils like petroleum. The importance of selecting the right packaging machinery is discussed, ranging from semi-automatic filling machines to fully automatic packaging lines, ensuring an efficient and safe oil packaging process.

Packaging Edible Oils: Technology and Machinery

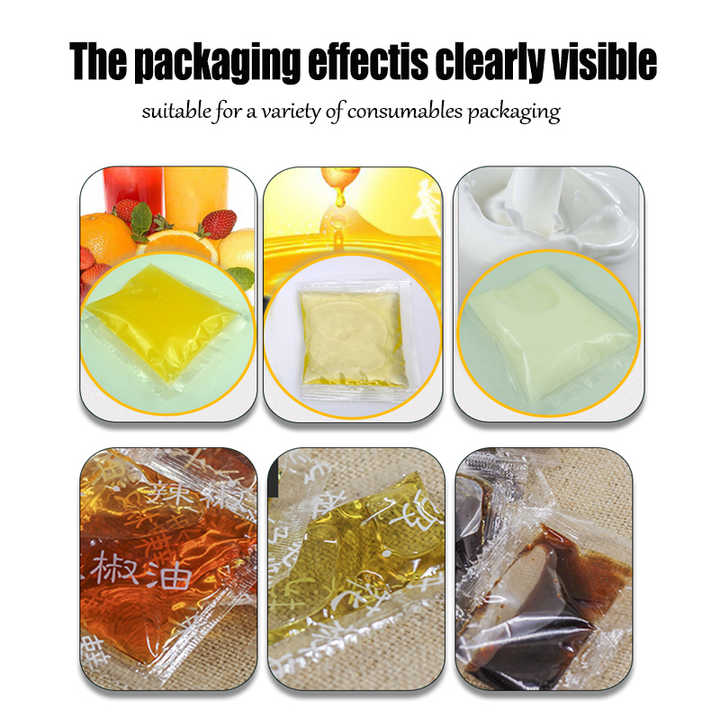

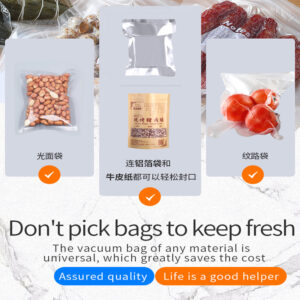

Edible oils, extracted from plants or animals, are typically packaged in bottles or pouches. Oil pouch packaging machines are key tools for filling small oil pouches, utilizing pipelines to transfer the oil, and offering sealing methods such as back sealing, three-side sealing, and four-side sealing. The filling capacity depends on the liquid pump model and the size of the pouch.

Packaging Non-Edible Oils: Safety and Efficiency

Non-edible oils, such as petroleum used as fuel or bath oils made from plants and minerals, require specialized packaging to ensure safety and efficiency. The packaging machinery for these oils is designed to handle their unique properties, often featuring additional safety and environmental protection functions.

Choosing the Right Packaging Machinery

PPM Machinery offers a range of oil filling machines, from semi-automatic models suitable for small-scale operations to automatic multi-head filling machines for multi-variety production. These machines can also integrate corresponding filling, sealing, and labeling production equipment, providing a comprehensive packaging automation solution.

Automation Enhances Packaging

Automation in oil packaging has increased efficiency and accuracy. Machinery with advanced features such as servo film transport systems and PLC touchscreen controls can precisely position and set parameters, resulting in high-quality packaging with consistent packaging weights.

Sustainability in Oil Packaging

The sustainability of oil packaging is becoming increasingly important, focusing on the use of eco-friendly materials and processes. Biodegradable materials and energy-saving machinery are becoming industry standards, reflecting the growing consumer demand for environmentally responsible products.

Customization and Innovation in Oil Packaging

Customization is key in the oil packaging industry, and PPM Machinery can customize it to specific product needs. Innovations such as smart labeling and adaptive filling technologies are changing the way oils are packaged, offering new opportunities for brand differentiation and consumer engagement.

Conclusion

Choosing the right oil packaging machinery is crucial for safely and efficiently handling various types of oils. By selecting the appropriate equipment and adopting innovative packaging practices, businesses can ensure product quality while meeting consumer expectations and environmental standards.