In this blog post, we delve into the world of flour packaging, exploring the various machinery and techniques used for efficient and hygienic packaging of this essential ingredient. From small packets to large bags, we examine the equipment that ensures flour reaches consumers in optimal condition, considering sustainability and operational efficiency.

Overview of Flour Packaging Machinery

Flour, a fundamental component in countless culinary creations, is typically sold in a variety of sizes in supermarkets and grocery stores. The packaging process plays a crucial role in maintaining the quality and freshness of flour, choosing mechanical equipment vital for both small-scale and large-scale operations.

Large Bag Packaging Equipment for Flour

For larger quantities of flour, usually in woven bags ranging from 5 kg to 50 kg, the process involves filling and sealing machinery that uses precise weighing systems to ensure each bag contains the correct amount of flour. Integrated sewing machines are commonly used to seal the bags, while conveyor belt systems aid in transportation and sealing.

Automatic Small Packaging Machines for Flour

For smaller quantities of flour, typically 1-3 kg, plastic small packaging is a suitable option. The Weigh and Fill Machine for Powder Flour is the preferred choice for this application, offering high efficiency and output. These machines handle the entire process from filling to sealing and can be paired with dry food grinders for added functionality.

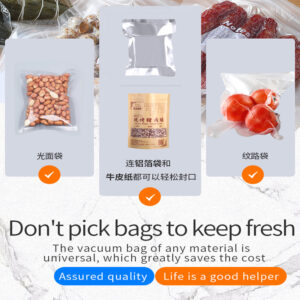

Vacuum Packaging Machines for Flour

Vacuum packaging is a popular method for preserving flour as it extends shelf life and maintains freshness. Machines with dual vacuum chambers are more efficient than single-chamber models, featuring multiple sealing bars for faster operation. For a unique presentation, these machines can also be equipped with block molds, shaping flour into bricks of various weights.

Best Practices for Flour Packaging Machines

Handling flour, a fine powder can be challenging due to its tendency to disperse in the air. To mitigate this, it is recommended to use a dosing or vacuum feeder in conjunction with the packaging machine. These devices not only facilitate the loading process but also help keep the work environment clean by preventing flour from dispersing in the air.

Conclusion

Selecting the appropriate flour packaging machinery is essential for ensuring the product reaches consumers in the best possible condition. By considering factors such as efficiency, accuracy, and cleanliness, businesses can enhance their operations and meet consumer expectations. For more information on flour packaging solutions, feel free to contact us at any time.